Four automated placement systems available with Vision Systems capable of inspecting solder ball coverage. One automated

systems available with 3-D laser capable of inspecting solder ball height Automatic placement of CBGA, PBGA and MBGA

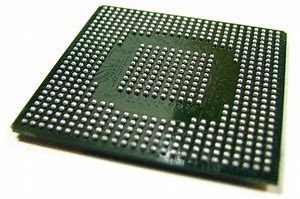

Verification of BGA’s using Phoenix real-time x-ray system. Ball Grid Array (BGA) style circuit boards, which used small circular balls

of solder to allow the flow of electricity between parts of the circuit. This brought with it a number of advantages to PCB assembly:

Higher-density circuits: As through-hole circuits were more densely-populated,

soldering them accurately without crossover or short-circuits became nearly

impossible. Heat conduction: BGA circuits allow heat to pass much more easily

from the integrated circuit outwards, reducing overheating problems. Lower

inductance: Because each solder ball in an BGA circuit is generally only a

handful of millimeters large, problems from interference within the circuit are

greatly minimized